Pipeline Welding Inspection: Ensuring Safety and Quality in Every Weld

Best Practices for Pipeline Welding Inspection: Methods, Standards, and Treatments to Achieve Top Quality Assurance and Conformity

Effective pipeline welding examination is necessary for ensuring the stability and safety of crucial infrastructure. Comprehending the intricacies involved in each phase of inspection is vital to achieving compliance and reliability in pipeline systems.

Significance of Welding Evaluation

The integrity of welded joints is vital in ensuring the safety and integrity of pipe systems. Appropriate welding strategies and comprehensive evaluation processes are important to avoid failings that can lead to devastating cases, ecological damages, and loss of life. Pipeline Welding Inspection. Welding examination functions as a safety net, recognizing problems such as cracks, porosity, and insufficient combination prior to they intensify right into serious problems

Moreover, pipeline systems typically operate under high pressure and severe conditions, making the top quality of welds also much more vital. Regulatory conformity is an additional significant facet, as numerous criteria determine the quality assurance processes that need to be abided by in pipe building and maintenance. Failure to conform can lead to lawful ramifications and financial losses.

The role of welding examination extends beyond mere confirmation of handiwork; it includes the assurance of lasting functional stability. This involves a methodical strategy that includes not just aesthetic examinations but likewise advanced non-destructive testing approaches. Ultimately, effective welding examination is an investment in the longevity and safety of pipe systems, guaranteeing they work as planned while decreasing threats related to material shortages.

Secret Evaluation Techniques

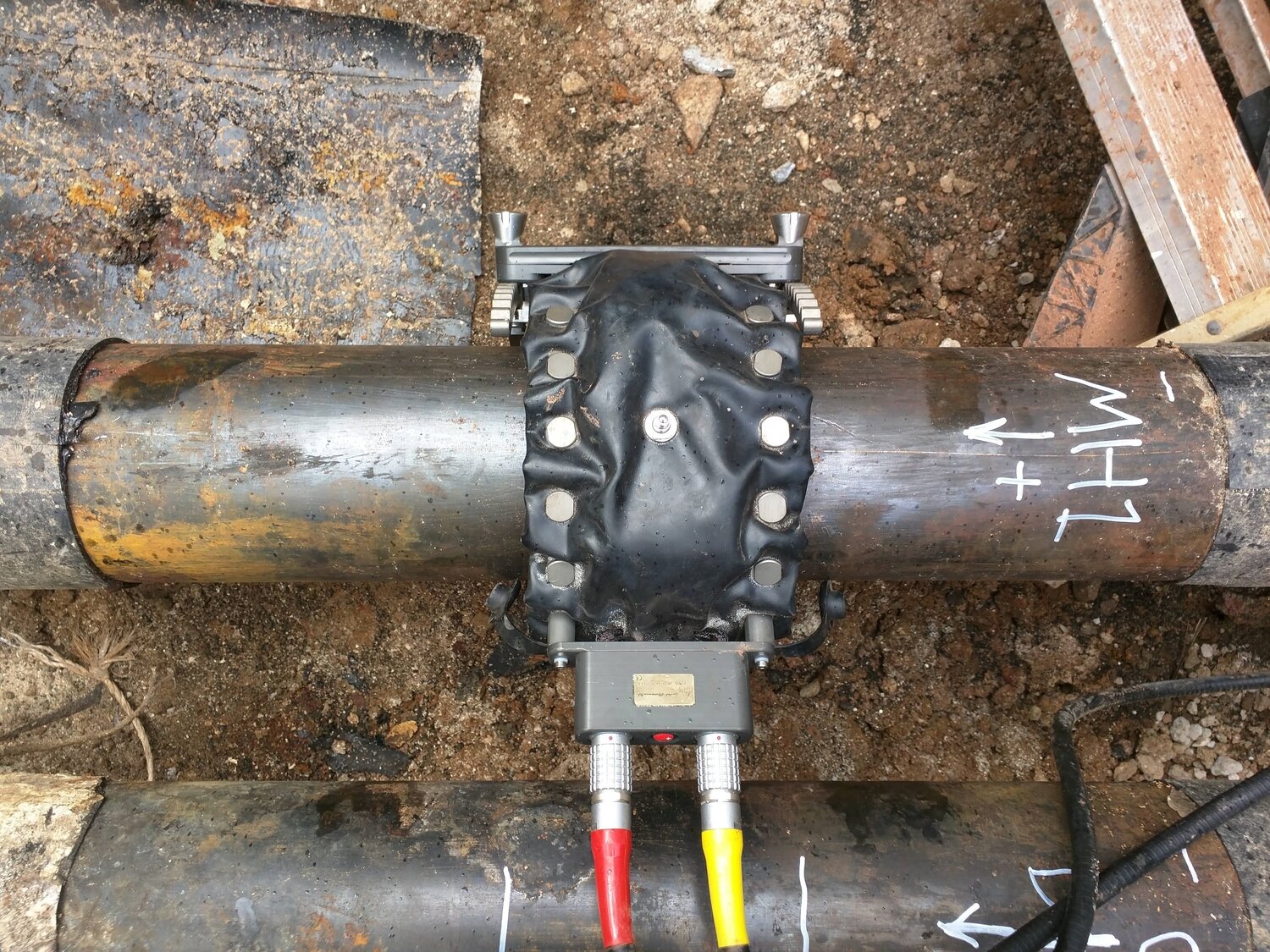

Aesthetic examination, typically the initial line of defense, enables for the identification of surface area flaws such as cracks, damages, and porosity. Ultrasonic testing uses high-frequency acoustic waves to spot inner problems, using a complete assessment of weld stability. This non-destructive technique is particularly effective for determining suspensions that may not be visible externally.

Radiographic screening includes making use of X-rays or gamma rays to generate pictures of the welded joint, disclosing internal issues. This method supplies thorough understandings but might call for customized equipment and safety and security factors to consider. Finally, magnetic particle screening works for spotting surface and near-surface stoppages in ferromagnetic products, making use of magnetic fields and great iron bits.

Market Specifications and Regulations

Conformity with market requirements and policies is vital for guaranteeing the high quality and safety and security of pipeline welding assessments. These requirements give a framework for best methods in welding procedures, products, and inspection methods, allowing companies to minimize problems and improve the stability of pipe systems. Trick bodies such as the American Culture of Mechanical Engineers (ASME), the American Welding Culture (AWS), and the International Organization for Standardization (ISO) state standards that are commonly recognized and embraced within the market.

In the USA, policies from the Pipe and Hazardous Materials Safety And Security Management (PHMSA) control the safety and security of pipe procedures, mandating strenuous inspection protocols. These requirements not just offer to protect public safety and the environment but also ensure compliance with legal and legal commitments. Adherence to the relevant codes, such as ASME B31.3 for procedure piping, is essential important link for maintaining functional performance and governing conformity.

Additionally, continuous updates and modifications to these standards mirror technical innovations and developing market practices, stressing the need for companies to stay educated and train workers accordingly. Eventually, robust conformity with established criteria cultivates trust fund and reliability in pipe framework, protecting both assets and stakeholders.

Effective Assessment Procedures

Efficient examination treatments are critical for determining possible problems in pipe welds and making certain the general honesty of the system. An organized approach to assessment incorporates a number of essential phases, consisting of pre-weld, in-process, and post-weld evaluations. Each phase plays an essential duty in maintaining high quality assurance.

Throughout pre-weld examination, it is vital to examine the products and joint configurations, making certain conformity with job specs. In-process assessments include monitoring welding strategies and specifications, such as warm input and travel speed, to stop flaws from happening. This phase permits real-time changes to welding techniques.

Post-weld examinations consist of non-destructive screening (NDT) strategies like radiography, ultrasonic screening, and magnetic bit testing. These methods assist discover inner and surface area flaws that can compromise the pipe's functionality. Documentation of all assessment activities is critical, providing a deducible document that sustains compliance with sector requirements.

Training and certification of inspection workers further improve the efficiency of these procedures. By sticking to a structured assessment protocol, organizations can reduce threats, make sure compliance, and ultimately supply pipes that fulfill strict security and efficiency demands.

Common Difficulties and Solutions

Pipeline welding assessment presents numerous typical obstacles that can affect the top quality and try this web-site safety and security of the end product. One substantial obstacle is the variability in welding strategies and products, which can lead to inconsistent weld quality. To resolve this, it is critical to develop standardized treatments and training for welders, making certain an uniform strategy across projects.

Ecological factors, including temperature and humidity, can also affect the welding procedure, potentially resulting in fractures or insufficient blend. Executing controlled environments and sticking to pre-weld treatments can mitigate these threats.

Verdict

Finally, the implementation of finest practices for pipeline welding assessment is important for ensuring quality control and conformity with market standards. A comprehensive method, integrating various techniques such as aesthetic, ultrasonic, and radiographic screening, facilitates the recognition of problems throughout all stages of the welding procedure. Pipeline Welding Inspection. Adherence to developed regulations have a peek at this site and effective examination treatments not only enhances the reliability and safety of pipeline systems yet also alleviates threats connected with welding defects, consequently promoting overall functional honesty

Conformity with industry requirements and regulations is essential for making certain the high quality and security of pipe welding assessments. These criteria supply a framework for best methods in welding processes, materials, and evaluation strategies, enabling companies to lessen flaws and enhance the honesty of pipeline systems.In the United States, policies from the Pipe and Hazardous Products Security Administration (PHMSA) regulate the safety of pipeline procedures, mandating strenuous evaluation protocols. A systematic technique to inspection includes several essential phases, including pre-weld, in-process, and post-weld inspections.In conclusion, the execution of best techniques for pipeline welding examination is essential for guaranteeing top quality assurance and conformity with industry criteria.